Rubber Quad Rings

Price 70 INR/ Piece

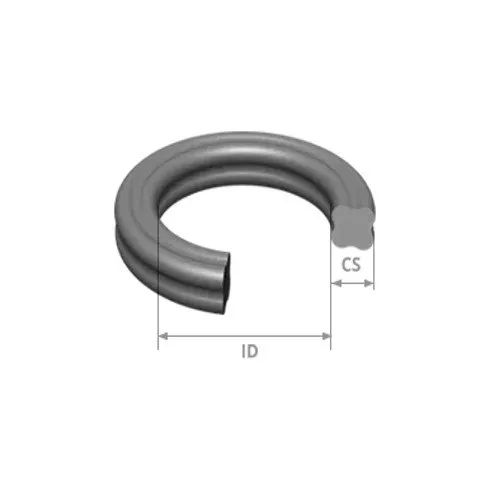

Rubber Quad Rings Specification

- Tolerance

- 0.05 mm

- Thickness

- 1 mm to 20 mm

- Standard

- ISO 3601/AS 568

- Material

- Nitrile Rubber (NBR), Silicone, EPDM, Viton

- Shape

- Quad (X-shaped)

- Hardness

- 60 to 90 Shore A

- Temperature

- -40C to +220C (material dependent)

- Function

- Sealing, Hydraulic and Pneumatic Sealing

- Application

- Hydraulic Cylinders, Pneumatic Systems, Valves, Pumps, Flanges

- Durometer Range

- 60-90 Shore A

- Compression Set

- <25% at 70°C for 22h

- Surface Finish

- Smooth/Matte

- Cross Section Dimensions

- 1.5 mm to 12 mm

- Elongation at Break

- 200% to 400%

- Media Compatibility

- Resistant to Oil, Water, Air, Some Chemicals

- Tensile Strength

- Up to 17 MPa

- Color

- Black, Red, Brown, Custom

Rubber Quad Rings Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 5000 Pieces Per Week

- Delivery Time

- 3 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

About Rubber Quad Rings

We offer a large variety of exactitude engineered a wide variety of exclusive cost efficient Rubber Quad Rings. These Rubber Quad Rings are manufactured by supreme quality of raw material which is brought from the most trusted and most well known vendors. These Rubber Quad Rings are very fine in functionality which makes them very demanded in the several areas of various industries. Depending upon the type of usage these Rubber Quad Rings can be availed in a range of sizes. Our company provides these Rubber Quad Rings in reasonable range of prices.Features:

Long life service

Easily available

Cost efficient

High performance

Additional Information:

Minimum Order Quantity: 100 Piece(s)

Optimized Sealing Performance

With their distinct Quad (X-shaped) profile, these rubber rings provide four sealing lips, reducing friction and wear compared to standard O-rings. Ideal for dynamic or static applications, they maintain tight seals under fluctuating pressures and temperatures, and their smooth surface finish promotes efficient installation and long-term reliability.

Versatile Material Options & Applications

Available in NBR, Silicone, EPDM, and Viton, these Quad Rings are engineered for use in hydraulic cylinders, pneumatic systems, valves, pumps, and flanges. Their broad material compatibility lets you select the right seal for oil, water, air, and select chemicals, ensuring optimal performance in demanding industrial environments.

FAQs of Rubber Quad Rings:

Q: How do Rubber Quad Rings improve sealing compared to traditional O-rings?

A: The unique Quad (X-shaped) design of these rings offers four contact sealing points, reducing friction and enhancing leak prevention. This configuration also minimizes extrusion and improves longevity, making them superior in dynamic and static sealing situations over standard O-rings.Q: What is the process for choosing the appropriate color and material for my application?

A: Select the color for visual identification or aesthetic preferences; choose from black, red, brown, or custom. For material, consider your applications media compatibility and operational temperatures: NBR for oils, EPDM for water and steam, Viton for chemicals, and Silicone for broad temperature ranges. Consult the manufacturer for specific project guidance.Q: When should custom dimensions or tolerances be specified for Quad Rings?

A: Custom dimensions or tight tolerances (0.05 mm) are necessary when your sealing application demands precise fitment, unusual cross-sections, or thicknesses outside standard offerings. Customization ensures optimal sealing efficiency and compatibility with unique equipment specifications.Q: Where are Rubber Quad Rings commonly used in industrial equipment?

A: These Quad Rings are widely used in hydraulic cylinders, pneumatic systems, valves, pumps, and flanges, providing dependable sealing in equipment susceptible to fluid or gas leakage. Their broad compatibility makes them a versatile solution across multiple sectors, including manufacturing and processing industries.Q: What benefits do Quad Rings offer in challenging temperature and pressure environments?

A: Quad Rings withstand temperatures from -40C up to +220C (material dependent) and pressures associated with hydraulic and pneumatic systems. Their low compression set and high elongation at break ensure reliable sealing, maintaining performance in fluctuating conditions and extending service intervals.Q: How are these Quad Rings manufactured to ensure quality and standard compliance?

A: Manufactured in India, each Quad Ring is produced according to ISO 3601 and AS 568 standards, utilizing advanced molding techniques and quality checks for precise tolerances, durometer range, and dimensional accuracy. This ensures every seal delivers consistent, high-performance results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Seals Category

Packing Rings

Price 150 INR / Piece

Minimum Order Quantity : 100 Pieces

Shape : Round, Flat, Square, Rectangular

Application : Pumps, Valves, Flanges, Pressure Vessels, Chemical Processing Equipment

Tolerance : 0.02 mm

Rubber Sealing Rings

Price 30 INR / Piece

Minimum Order Quantity : 100 Pieces

Shape : Round

Application : Hydraulic, Pneumatic, Automotive and Industrial Machinery

Material : High Grade Rubber (NBR, EPDM, Silicone, or Neoprene)

Tolerance : 0.05 mm

Rubber Roller

Minimum Order Quantity : 1 Unit

Shape : Round

Application : Industrial

Material : Rubber

Butterfly Valve Sleeve

Shape : Round

Application : Water supply, wastewater, chemical, and food industries

Material : EPDM Rubber, Nitrile, Neoprene, Silicone

Tolerance : 0.2 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS