Butterfly Valve Sleeve

Butterfly Valve Sleeve Specification

- Thickness

- 3 mm to 12 mm

- Standard

- IS, DIN, ASTM

- Tolerance

- 0.2 mm

- Material

- EPDM Rubber, Nitrile, Neoprene, Silicone

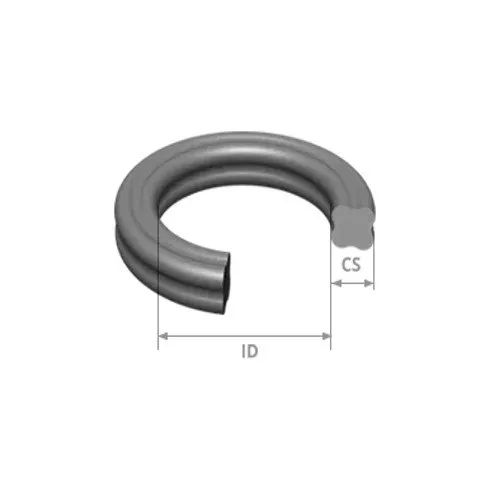

- Shape

- Round

- Application

- Water supply, wastewater, chemical, and food industries

- Installation Type

- Push Fit or Molded

- Media Compatibility

- Water, oil, mild chemicals

- Color

- Black, Red, White

- Finish

- Smooth, Uniform

- Pressure Rating

- Up to 16 bar

Butterfly Valve Sleeve Trade Information

- Main Domestic Market

- South India

About Butterfly Valve Sleeve

Empowered by a team of skilled professionals and lading-edge technology, we are presenting premium quality Butterfly Valve Sleeve. This valve sleeve is manufactured using optimum quality metals and advanced technology. Made available in different sizes and specifications as per the detailed provided by the clients spanning across the globe. Our offered Butterfly Valve Sleeve is tested on well defined parameters in order to ensure flawlessness at the client' s end.

Features:

-

Dimensionally accurate

-

Highly durable

-

Simple usage

-

Seamless finish

Reliable Sealing Solution

Our butterfly valve sleeves guarantee a leak-proof fit, thanks to their precise 0.2 mm tolerance and uniform thickness. The sleeves push-fit or molded installation streamlines the process, ensuring a consistent, durable seal that effectively handles a pressure rating up to 16 bar.

Versatile Media Compatibility

Engineered to perform with water, oil, and mild chemicals, these sleeves are designed to suit multiple industrial requirements. Their chemical-resistant materialsEPDM Rubber, Nitrile, Neoprene, and Siliconemake them suitable for diverse conditions, providing longevity and peace of mind.

Quality Standards and Durability

Each sleeve adheres to major international standards such as IS, DIN, and ASTM. The smooth, uniform finish not only enhances aesthetics but also improves operational efficiency by reducing friction and wear, contributing to extended service life.

FAQs of Butterfly Valve Sleeve:

Q: How are butterfly valve sleeves installed?

A: Butterfly valve sleeves are designed for either push-fit or molded installation, ensuring a secure, seamless fit. Push-fit types can be easily inserted without special tools, saving on installation time and labor.Q: What materials are available for the butterfly valve sleeves, and how do I choose the right one?

A: These sleeves are made from EPDM Rubber, Nitrile, Neoprene, or Silicone. Selection depends on the application: EPDM is best for water, Nitrile for oil, Neoprene and Silicone for wider chemical compatibility and food-safe uses.Q: When should I replace the butterfly valve sleeve?

A: Replacement is recommended during scheduled maintenance or if there are signs of leakage, wear, or loss of elasticity. Regular checks ensure optimal performance and avoid downtime in critical applications.Q: Where can these butterfly valve sleeves be used?

A: These sleeves are ideal for water supply, wastewater treatment, chemical processing, and the food industry, providing a versatile sealing solution for processes involving water, oil, or mild chemicals.Q: What is the manufacturing process for these sleeves?

A: Our sleeves are produced using high-quality rubber compounds molded or extruded to precise thicknesses (312 mm). They undergo rigorous quality checks to ensure conformance to IS, DIN, and ASTM standards, delivering a smooth, uniform finish.Q: What are the benefits of using these valve sleeves?

A: The sleeves offer excellent leak resistance, support high pressure up to 16 bar, and provide a lasting seal in corrosive settings. Their chemical compatibility and compliance with global standards make them a dependable choice for critical systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Seals Category

Rubber Diaphragm

Price 50 INR / Piece

Minimum Order Quantity : 100 Pieces

Standard : IS, ASTM, DIN

Function : Sealing, Pressure Control, Isolation

Tolerance : 0.1 mm

Application : Valves, Pumps, Actuators, Regulators, Industrial Machinery

Rubber Quad Rings

Price 70 INR / Piece

Minimum Order Quantity : 100 Pieces

Standard : ISO 3601/AS 568

Function : Sealing, Hydraulic and Pneumatic Sealing

Tolerance : 0.05 mm

Application : Hydraulic Cylinders, Pneumatic Systems, Valves, Pumps, Flanges

Tyre Flaps

Standard : IS:5914

Function : Protect tube from direct contact with rim

Tolerance : 0.2 mm

Application : Automotive tyres

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS