Rubber Diaphragm

Price 50 INR/ Piece

Rubber Diaphragm Specification

- Thickness

- 1 mm to 10 mm

- Tolerance

- 0.1 mm

- Standard

- IS, ASTM, DIN

- Material

- Nitrile Rubber, Neoprene, EPDM, Silicone

- Shape

- Round, Rectangular, Customized

- Hardness

- 40 to 90 Shore A

- Temperature

- -40C to +200C

- Function

- Sealing, Pressure Control, Isolation

- Application

- Valves, Pumps, Actuators, Regulators, Industrial Machinery

- Reinforcement

- With or Without Fabric Reinforcement

- Resistance

- Aging, Ozone, UV, Weather

- Elongation at Break

- 200% to 500%

- Compression Set

- < 25% (at specified temperature)

- Media Compatibility

- Water, Oil, Gas, Chemicals

- Color

- Black, Red, White, Custom

- Tensile Strength

- 8-15 MPa

- Finish

- Smooth, Textured

Rubber Diaphragm Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 5000 Pieces Per Week

- Delivery Time

- 3 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

About Rubber Diaphragm

Being a client-centric organization, we are passionately engaged in providing our clients a premium quality Rubber Diaphragm. Our team of qualified professionals manufacture the offered diaphragm by making use of the best quality rubber and other allied material with modern technology. This is made available in different technical specifications and used in various factories and other automobile industries for various types of fitting and sealing purposes. Moreover, clients can avail this Rubber Diaphragm at reasonable prices.

Features:

-

Light weight

-

Perfect finish

-

Durable nature

-

Easy fitting

Engineered for Versatile Industrial Use

These rubber diaphragms are designed to provide reliable sealing, isolation, and pressure control in a range of applications, including valves, pumps, actuators, and regulators. Their superior elasticity and compression set of less than 25% ensure consistent performance even under challenging operating conditions.

Customizable to Meet Precise Specifications

Choose from a wide selection of colors, finishes, thicknesses, and shapes to match your application requirements. Both reinforced and non-reinforced options are available to deliver enhanced durability or flexibility, suited to diverse industrial environments.

Durable Performance in Extreme Environments

Manufactured from premium nitrile, neoprene, EPDM, or silicone, our diaphragms function flawlessly across temperatures from -40C to +200C. Engineered to resist aging, ozone, UV, and weather, they maintain integrity and functionality for extended operational lifespans.

FAQs of Rubber Diaphragm:

Q: How can rubber diaphragms be used in industrial machinery?

A: Rubber diaphragms provide essential sealing, pressure control, and isolation functions in industrial machinery, ensuring safe and efficient operation in valves, pumps, actuators, and regulators by preventing leaks and maintaining pressure differentials.Q: What materials are available for these rubber diaphragms?

A: Our diaphragms are available in nitrile rubber, neoprene, EPDM, and silicone, each offering specific benefits such as chemical resistance, flexibility over wide temperature ranges, and robustness against aging and environmental exposure.Q: When should fabric-reinforced diaphragms be selected?

A: Fabric-reinforced diaphragms are recommended for applications requiring enhanced mechanical strength and durability, particularly in high-pressure or cyclic environments where additional stability is essential.Q: Where are these diaphragms manufactured, and do they meet international standards?

A: These diaphragms are manufactured in India and conform to international standards like IS, ASTM, and DIN, ensuring consistent quality and compatibility for global market requirements.Q: What is the process for customizing rubber diaphragms?

A: You can specify color, shape, thickness, finish, material, reinforcement, and tolerance requirements. Our manufacturing process accommodates both standard and specialized designs to meet precise operational needs.Q: How does the diaphragm benefit from a compression set below 25%?

A: A low compression set ensures the diaphragm maintains its shape and sealing ability after repeated deformation, which reduces the risk of leakage and extends service life in dynamic industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Seals Category

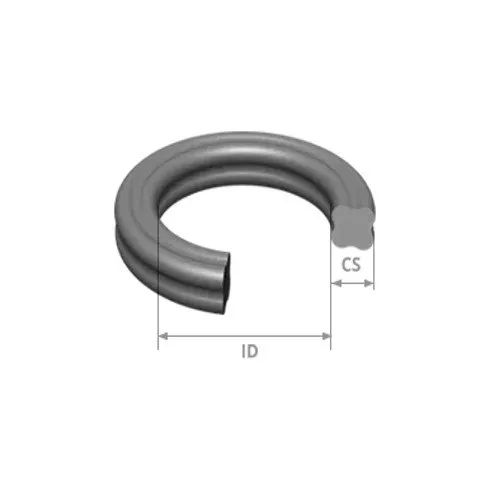

Rubber Quad Rings

Price 70 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Hydraulic Cylinders, Pneumatic Systems, Valves, Pumps, Flanges

Shape : Quad (Xshaped)

Tolerance : 0.05 mm

Standard : ISO 3601/AS 568

Industrial Rubber Bellows

Price 40 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Pipelines, Ducts, Pumps, Industrial Machinery

Shape : Cylindrical / Custom

Tolerance : 0.1 mm

Standard : IS 5382 / DIN 4809

Rubber Metal Bonding

Price 20 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Automotive, Railways, Industrial Machinery, Electrical, Construction

Shape : Round, Rectangular, Custom

Tolerance : 0.05 mm

Standard : IS, ASTM, DIN

Rubber Pad

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Machinery Base, Automobile, Industrial Flooring

Shape : Rectangular

Tolerance : 0.5 mm

Standard : IS 15652

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS