Rubber Coupling

Rubber Coupling Specification

- Thickness

- 10 mm

- Standard

- IS 2957

- Tolerance

- 0.1 mm

- Shape

- Round

- Function

- Power transmission and vibration damping

- Application

- Pumps, compressors, conveyors, industrial machinery

Rubber Coupling Trade Information

- Main Domestic Market

- South India

About Rubber Coupling

Since the day of our inception in the year 1988, we are able to manufacture, export and supply an optimum quality Rubber Coupling. The offered coupling is manufactured in adherence with the international standards, using high grade rubber materials. This is highly acknowledged among the clients for their usage in different factories and automobile industries. Clients can also avail this Rubber Coupling from us at market leading rates across the globe.

Features:

-

Excellent strength

-

Easy fitting

-

Elevated durability

-

Impeccable finish

Exceptional Wear Resistance and Flexibility

Designed for demanding industrial environments, this rubber coupling delivers outstanding wear resistance and flexibility. It effectively absorbs shocks and minimizes wear, ensuring longer service life even under rigorous operating conditions, such as in pumps, compressors, and conveyors.

Reliable Power Transmission and Vibration Damping

The couplings primary function is to transmit power between shafts while reducing vibration. Its smooth, rubber construction and flexible jaw design guarantee efficient torque transfer and stable operation, helping to protect both the machinery and the coupling from damage.

Quality Manufacturing and Precise Standards

Manufactured in India to IS 2957 standards, this rubber coupling undergoes strict quality control. Its tolerance of 0.1 mm and smooth finish ensure consistent, reliable performance. Packaged securely in box or carton for safe transportation and storage.

FAQs of Rubber Coupling:

Q: How is this rubber coupling installed in industrial machines?

A: The rubber coupling is easily installed by connecting its flexible jaws between the motor and driven shaft, securely fitting the round 80 mm diameter unit in place to help manage misalignments and dampen vibrations.Q: What applications are best suited for this black rubber coupling?

A: This coupling is ideally used in pumps, compressors, conveyors, and other industrial machinery where power transmission and vibration damping are critical for efficient operation.Q: When should the rubber coupling be replaced during machine maintenance?

A: Replacement is recommended when visible signs of wear, cracking, or reduced damping capacity are observed, or as per the machinery manufacturers scheduled maintenance guidelines.Q: Where can I purchase this 80 mm diameter rubber coupling from India?

A: You can source this coupling directly from manufacturers based in India, either through their authorized distributors, online platforms, or local industrial suppliers.Q: What process ensures the quality and precision of these couplings?

A: Each coupling is produced according to IS 2957 standards, featuring rigorous inspections for tolerance (0.1 mm), uniform thickness, and a smooth surface finish to guarantee reliable function and longevity.Q: How does the coupling benefit machinery performance?

A: The rubber coupling provides power transmission while efficiently damping vibrations, reducing wear on machine components, accommodating shaft misalignments, and extending equipment lifespan.Q: Is this coupling resistant to oil and grease, and what does that mean for usage?

A: Yes, it is engineered for oil and grease resistance, ensuring reliable operation even in environments exposed to lubricants, thereby maintaining coupling integrity and reducing maintenance needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Seals Category

Rubber Quad Rings

Price 70 INR / Piece

Minimum Order Quantity : 100 Pieces

Shape : Quad (Xshaped)

Application : Hydraulic Cylinders, Pneumatic Systems, Valves, Pumps, Flanges

Standard : ISO 3601/AS 568

Tolerance : 0.05 mm

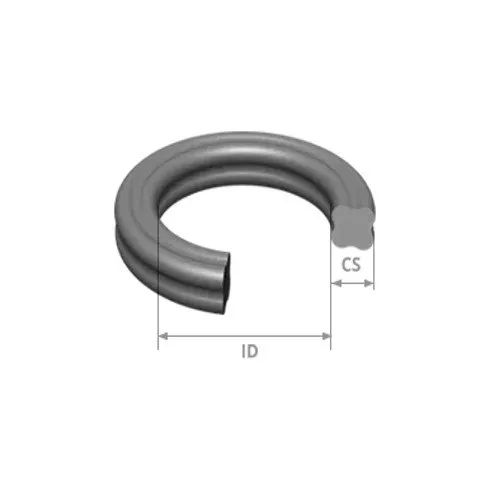

Rubber Sealing Rings

Price 30 INR / Piece

Minimum Order Quantity : 100 Pieces

Shape : Round

Application : Hydraulic, Pneumatic, Automotive and Industrial Machinery

Standard : IS 5382 / DIN 3771

Tolerance : 0.05 mm

Rubber Pad

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Shape : Rectangular

Application : Machinery Base, Automobile, Industrial Flooring

Standard : IS 15652

Tolerance : 0.5 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free